2025-08-18

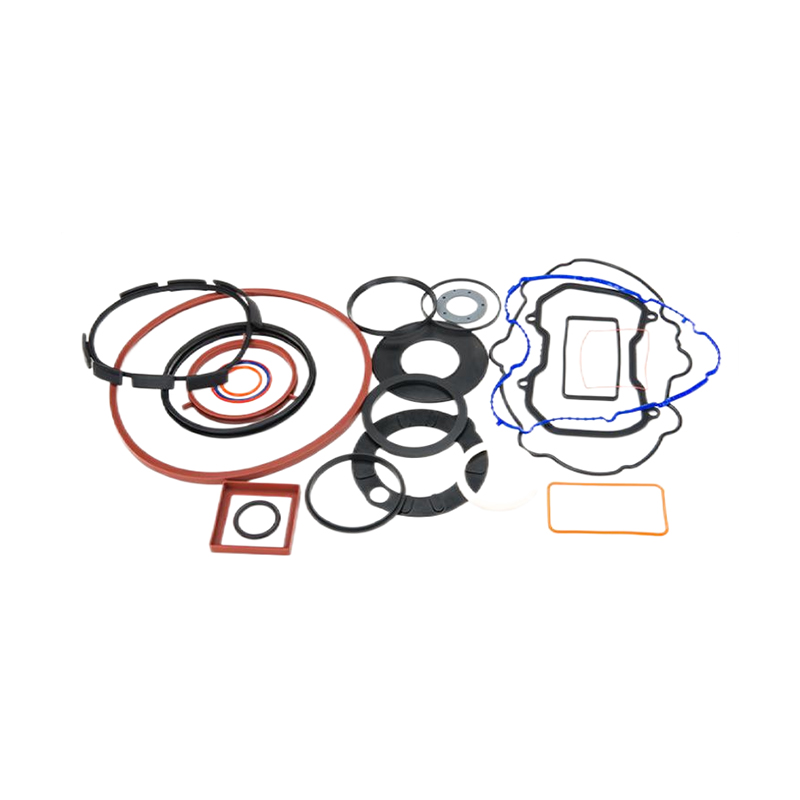

In the intricate web of modern industry, where pipelines crisscross like arteries and machinery hums with relentless energy, there exists a class of components so humble they’re often overlooked—yet so critical they can make or break an entire system. Rubber gaskets, seals, and washers may seem unassuming, but they are the silent guardians of industrial integrity. These elastic workhorses fill microscopic gaps between metal flanges, seal rotating shafts against fluid leakage, and cushion connections to prevent wear. From the high pressure steam lines of power plants to the precision valves of pharmaceutical factories, from the hydraulic systems of construction machinery to the plumbing networks in our homes, they ensure that liquids, gases, and even contaminants stay exactly where they belong. A single failing seal can trigger catastrophic leaks, costly downtime, environmental hazards, or even safety incidents. Thus, understanding their role, selecting the right type, and prioritizing quality isn’t just a matter of efficiency—it’s a cornerstone of responsible industrial operation.

Rubber gaskets are the unsung heroes of leak prevention, forming the first line of defense in countless industrial systems. Their core function is deceptively simple: to compress between two mating surfaces (such as flanges, lids) and fill irregularities, creating an impenetrable barrier. But their impact is profound.

Consider a chemical processing plant, where corrosive acids flow through miles of piping. A properly selected rubber gasket—resistant to the specific chemical, temperature, and pressure of the line—prevents toxic leaks that could harm workers or pollute nearby ecosystems. In power generation facilities, high-temperature steam pipes rely on gaskets to contain pressurized vapor; a failure here could lead to explosions or shutdowns costing millions. Even in everyday plumbing, rubber washers in faucets or valves ensure that water flows where intended, avoiding waste and water damage.

Beyond leak prevention, rubber gaskets also absorb vibrations, reducing wear on metal components and extending equipment lifespans. Their elasticity allows them to adapt to thermal expansion and contraction, maintaining a tight seal even as temperatures fluctuate. In short, these small components are the glue that holds industrial systems together, making them non-negotiable for safety, efficiency, and sustainability.

Not all rubber is created equal. The key to effective sealing lies in matching the material to the工况 (operating conditions)—and industrial environments are notoriously unforgiving. From scorching heat to freezing cold, from aggressive chemicals to heavy oil exposure, the right material can mean the difference between a seal that lasts years and one that fails in weeks.

Fluoroelastomers (FKM/Viton®): The champions of high-temperature and chemical resistance. These materials thrive in environments up to 200°C (and even 260°C for short periods), making them ideal for aerospace engines, oil refinery valves, and industrial ovens. They also resist fuels, solvents, and acids, making them indispensable in harsh chemical processing.

Nitrile Rubber (NBR): The workhorse of oil resistance. Found in automotive engines, hydraulic systems, and fuel lines, NBR excels at withstanding petroleum-based fluids, greases, and mineral oils. It operates reliably between -40°C and 120°C, balancing performance with affordability—a favorite for industrial machinery.

EPDM (Ethylene Propylene Diene Monomer): The corrosion and weathering expert. EPDM stands strong against water, steam, ozone, and mild acids/alkalis, making it perfect for plumbing systems, outdoor equipment, and food processing (where FDA-approved grades are available). It handles temperatures from -50°C to 150°C, thriving in both freezing and boiling conditions.

Silicone Rubber (VMQ): The versatile all-rounder. Silicone offers excellent flexibility across a wide temperature range (-60°C to 230°C) and is biocompatible, making it ideal for medical devices, food-grade equipment, and high-heat applications like ovens or steam valves. While less chemical-resistant than FKM, its adaptability makes it a staple in diverse industries.

Neoprene (CR): The durable multi-tasker. Resistant to oil, ozone, and physical abrasion, neoprene is often used in gaskets for refrigeration systems, automotive door seals, and outdoor machinery. It balances flexibility with strength, performing well in temperatures from -40°C to 120°C.

Selecting the right material requires analyzing three critical factors: the medium (fluid/gas being sealed), temperature range, and pressure. A mismatch—like using NBR in a strong acid line—guarantees premature failure.

Flanged connections—where twoPipeline or equipment ends are joined with a flange and bolts—are ubiquitous in industrial piping. Here, flanged rubber gaskets are the linchpin of reliable sealing, designed to compress between the flanges and withstand the full force of the system’s pressure.

Standard flanged gaskets come in common sizes (e.g., ANSI, DIN, JIS) and materials, suitable for routine applications like water pipelines or low-pressure air systems. But many industrial setups demand customization. Non-standard flange sizes, irregular shapes, or extreme conditions (e.g., high-pressure steam with abrasive particles) require gaskets tailored to exact specifications.

Custom flanged rubber gasket manufacturing involves precision engineering:

For example, a refinery handling high-pressure crude oil might require a custom FKM gasket with a metal core for rigidity, while a food processing plant could need a FDA-approved EPDM gasket with a smooth surface to prevent bacterial buildup. Customization isn’t a luxury—it’s the only way to seal non-standard systems safely.

While gaskets handle large-scale flange sealing, rubber washers and sealing ring tackle more specialized roles, where precision is paramount.

Rubber Washers: These flat, disk-shaped components are often used under bolts, nuts, or faucets. Their primary roles? Distribute pressure to prevent surface damage, act as a buffer against vibrations, and provide basic sealing for low-pressure applications (e.g., plumbing pipes). For instance,rubber washers for plumbing must resist water, mild chemicals, and temperature changes to prevent drips.

Rubber Seals/O-Rings: Designed for dynamic or static sealing in tight spaces. O-rings, a common type, are circular and compress into grooves to block fluid flow—found in hydraulic cylinders, pumps, and valves. Unlike washers, they handle higher pressures and are critical for moving parts (e.g., a piston sliding in a cylinder).

The performance of both depends on meticulous details:

A single rubber component might seem trivial, but a holistic sealing strategy transforms industrial performance. Consider a manufacturing plant relying on hydraulic presses: industrial industrial-grade oil-resistant rubber seals in the hydraulic lines prevent oil leaks, ensuring consistent pressure and reducing downtime. In a pharmaceutical facility, EPDM gaskets in mixing tanks seal against sanitizing agents, maintaining sterile conditions and compliance with strict regulations.

Comprehensive solutions go beyond supplying parts—they involve collaboration between engineers and suppliers to:

The result? Reduced maintenance costs, fewer unplanned shutdowns, and enhanced safety. For businesses, this isn’t just about sealing—it’s about unlocking long-term reliability and competitiveness.

In the end, rubber gaskets, seals, and washers are more than mere components. They are the unsung architects of industrial stability, ensuring that the machines powering our world run safely, efficiently, and sustainably. Whether you’re procuring standard parts or seeking custom flanged gasket manufacturing , investing in quality and expertise isn’t an expense—it’s the foundation of industrial success.