2025-12-19

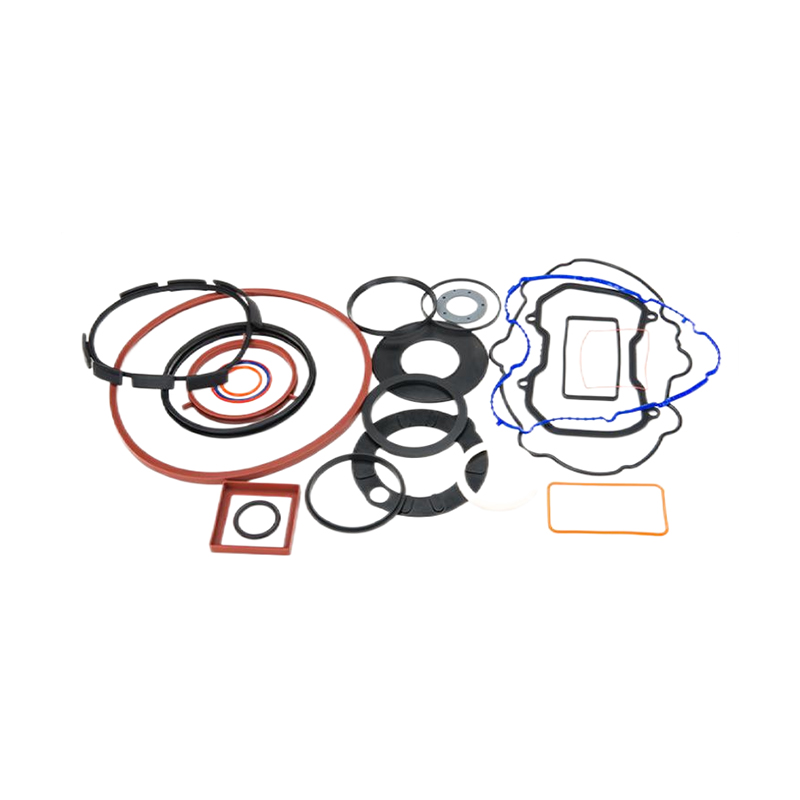

In the vast world of industrial components, few elements are as universally critical yet often overlooked as the humble rubber seal. These custom-engineered barriers stand as silent guardians against leakage, contamination, pressure loss, and environmental ingress. The journey from a concept to a reliable, high-performance custom rubber seal involves a sophisticated interplay of material science, precision engineering, and rigorous testing. This comprehensive guide delves deep into the specialized niche of custom rubber seals, exploring the key considerations for selection, the nuances of manufacturing, and their pivotal role across diverse sectors. We will also examine the capabilities of integrated manufacturers like Jiaxing Tosun Rubber&Plastic Co., Ltd., whose 15,000-square-meter facility and team of over 250 professionals, including 12 dedicated mold design and formulation engineers, exemplify the technical depth required to transform customer specifications into flawless, functional seals.

Custom rubber seals are far from being generic, off-the-shelf items. They are precision components engineered to solve specific challenges within a defined operational envelope. Their primary function is to create a secure, durable barrier between two or more surfaces, assemblies, or environments. This barrier must often perform under extreme conditions, which is why the "custom" aspect is non-negotiable for most industrial applications. A standard O-ring might suffice for a low-pressure water fixture, but critical machinery, automotive systems, or aerospace equipment demand seals tailored to exact dimensions, material properties, and performance criteria.

The limitations of standard seals become apparent when faced with real-world engineering challenges. A seal might need to maintain flexibility at -40°C, resist aggressive chemicals at 150°C, or endure constant dynamic friction for millions of cycles. Generic seals are designed for average conditions and common media. When applied to specialized scenarios, they can fail prematurely, leading to catastrophic system failures, costly downtime, and safety hazards. The decision to invest in custom seals is a decision for reliability, longevity, and total cost of ownership. It is an engineering choice that prioritizes system integrity over short-term cost savings on components.

The process of creating a custom seal is a collaborative engineering endeavor. It begins with a thorough understanding of the application's "boundary conditions." Engineers must consider not just the inner and outer diameters, but also the sealing force, the gland design, the compression set requirements, and the nature of the surfaces being sealed. For instance, a seal for a rotating shaft (dynamic) has fundamentally different design requirements than a seal for a static flange connection. The material must be chosen not only for its chemical compatibility but also for its extrusion resistance, permeability, and long-term aging characteristics under the specific service environment.

The heart of any rubber seal's performance lies in its material composition. Selecting the wrong elastomer is the most common cause of seal failure. The choice is a complex balance of physical properties, chemical resistance, temperature range, and cost. Each base polymer offers a unique profile, making it suitable for a distinct set of challenges.

Here is a comparative overview of key elastomer materials used in custom seal manufacturing:

| Elastomer Type | Temperature Range (Approx.) | Key Strengths | Typical Applications | Weaknesses |

|---|---|---|---|---|

| Nitrile Rubber (NBR) | -40°C to +120°C | Excellent resistance to oils, fuels, and greases; good abrasion resistance. | Automotive fuel systems, hydraulic seals, oil field equipment. | Poor resistance to ozone, sunlight, and weathering. |

| Fluoroelastomer (FKM/Viton®) | -20°C to +200°C | Exceptional chemical and heat resistance; low gas permeability. | Aerospace, chemical processing, high-temperature automotive. | Higher cost; poor low-temperature flexibility. |

| Silicone Rubber (VMQ) | -60°C to +225°C | Extremely wide temperature range; excellent flexibility; good electrical insulation. | Food & medical devices, high/low temp gaskets, appliance seals. | Low tensile strength; poor abrasion resistance. |

| Ethylene Propylene Diene Monomer (EPDM) | -50°C to +150°C | Superior resistance to water, steam, ozone, and weathering. | Outdoor electrical enclosures, cooling systems, automotive weather-stripping. | Poor resistance to most oils and hydrocarbons. |

| Polytetrafluoroethylene (PTFE) filled compounds | -200°C to +260°C | Nearly universal chemical inertness; extremely low friction. | Aggressive chemical seals, ultra-high purity systems, non-lubricated dynamic seals. | Can be prone to creep; requires precise gland design. |

As the table illustrates, the choice between Nitrile and FKM, for example, is stark. Nitrile rubber seals for fuel systems are the industry standard for gasoline and diesel resistance at moderate temperatures, offering a superb balance of performance and cost. Conversely, for an application involving hot, aggressive acids, FKM would be the unequivocal choice despite its higher price, as Nitrile would degrade rapidly. This decision matrix underscores why manufacturers like Jiaxing Tosun Rubber&Plastic Co., Ltd. employ dedicated formulation engineers. Their expertise allows them to not only select the base polymer but also to fine-tune the compound with specific fillers, plasticizers, and curing agents to meet exact customer specifications for hardness, compression set, or color.

Once the material is specified, the physical creation of the seal through precision molding is the next critical phase. The quality of the mold and the chosen molding process directly impact the seal's dimensional accuracy, surface finish, and internal integrity—factors that are crucial for high temperature silicone rubber gaskets and all precision seals.

The three most prevalent manufacturing techniques are Compression Molding, Injection Molding, and Transfer Molding. Each has its advantages and is selected based on the seal's geometry, production volume, and material.

The mold itself is a masterpiece of precision engineering. Mold designers must account for material shrinkage during curing, venting to allow gases to escape, and the placement of gates and runners (for injection/transfer molding) to ensure uniform filling. For a company like Jiaxing Tosun, with its team of 12 mold design engineers, the ability to quickly and accurately design molds from customer drawings or samples is a core competency. This rapid prototyping and tooling capability is what allows for the efficient production of truly custom solutions, ensuring the final seal matches the design intent perfectly.

The application of custom rubber seals spans virtually every sector of modern industry. Each sector presents a unique set of challenges that drive specific design and material requirements.

This industry is a major consumer of custom seals, demanding solutions that can withstand harsh under-hood temperatures, constant exposure to fuels and lubricants, and dynamic movement. Seals are found in engines (valve stem seals, gaskets), transmissions, fuel injection systems, electrification components, and throughout the vehicle's chassis and body. The push for electric vehicles (EVs) is creating new demands for seals that insulate high-voltage components and manage thermal interfaces in battery packs. The requirement for EPDM sponge rubber door seals is quintessential to this sector, providing the flexible, durable, and weather-tight closure necessary for passenger comfort and vehicle integrity. These seals must resist permanent compression set (so the door always closes tightly), endure UV degradation, and remain flexible in freezing conditions.

In this realm, seals face extreme pressures, reciprocating or rotating motion, and potential contamination. Hydraulic cylinder rod seals are a perfect example of a high-stakes custom application. They must contain fluid under pressures that can exceed 5,000 psi, prevent external contaminants from entering the cylinder, and exhibit minimal friction to ensure efficient operation. The choice of material—often polyurethane or specialized compounds—and the lip design are critical. A failure here can lead to hydraulic fluid leaks, loss of system pressure, component damage, and environmental hazards. Manufacturers serving this field must have robust testing protocols to validate seal performance under simulated operating conditions.

Here, sealing requirements transcend mere mechanical function. Materials must be non-toxic, non-absorbent, and compliant with stringent regulatory standards (such as FDA, USP Class VI, or EU 1935/2004). Silicone rubber is a frequent choice due to its inertness and wide temperature tolerance for sterilization (autoclaving). Seals in this sector often require ultra-smooth surfaces to prevent bacterial harborage and must be manufactured in cleanroom conditions to avoid particulate contamination. The design of food grade silicone rubber extrusions for processing equipment or packaging machinery highlights the need for custom profiles that are easy to clean, resistant to cleaning chemicals, and maintain a consistent seal to protect product purity.

The reliability of a custom rubber seal is only as good as the verification process behind it. Comprehensive testing is non-optional, moving beyond simple dimensional checks to evaluate performance under simulated or accelerated life conditions.

A rigorous QA program will include a combination of the following tests, often conducted both on raw materials and finished seals:

The presence of a dedicated technical inspection team, such as the 20-person team at Jiaxing Tosun, is a significant asset. It allows for continuous in-process checks during production and final batch certification before shipment. This internal capability ensures that every batch of custom rubber seals meets the agreed-upon specifications, providing the customer with consistent quality and performance, batch after batch. It transforms quality from a final inspection checkpoint into an integral part of the manufacturing culture.

The field of custom rubber sealing is not static. It is being shaped by powerful trends in material science, digitalization, and global industry needs. The development of new elastomer blends with enhanced properties—such as higher temperature resistance, improved environmental sustainability, or self-lubricating characteristics—is ongoing. Furthermore, the integration of Industry 4.0 principles into manufacturing allows for smarter production with real-time process monitoring, predictive maintenance for tooling, and full traceability of materials from source to finished seal. Companies that invest in both advanced material R&D and digital manufacturing infrastructure, as evidenced by comprehensive enterprises with strong R&D focus, are best positioned to lead in this evolving landscape. They will be the partners capable of delivering the next generation of sealing solutions for emerging challenges in sectors like renewable energy, advanced electronics, and sustainable transportation.