2026-02-11

The modern industrial landscape is built on the seamless, reliable operation of complex machinery and systems. Protecting sensitive components from harsh environments, accommodating movement, and ensuring the longevity of equipment are paramount concerns for engineers and maintenance professionals. Among the versatile solutions addressing these challenges, rubber bellows stand out as a critical, yet often understated, component. These flexible, accordion-like sleeves, typically crafted from elastomers like EPDM, Nitrile (NBR), Neoprene, or Silicone, serve as protective seals and covers for a wide array of applications. Their primary function is to shield pivotal components such as rod ends, linear actuators, ball screws, and universal joints from contaminants like dust, dirt, moisture, and chemicals while simultaneously permitting necessary axial, lateral, or angular movement. This article delves deep into the key advantages of integrating rubber bellows into industrial designs, exploring how they enhance performance, reduce downtime, and deliver significant long-term value across various sectors. By understanding their specific benefits, from preventing rubber bellows failure in harsh environments to optimizing the cost of custom rubber bellows for machinery, decision-makers can make more informed selections that bolster operational resilience and efficiency.

In industrial settings, the intrusion of particulate matter, liquids, and corrosive agents is a leading cause of premature component wear and system failure. A rod end exposed to abrasive metal chips or a precision slide contaminated with coolant can lead to catastrophic seizing or inaccuracies. Rubber bellows act as a dynamic, physical barrier, completely enclosing the component they are fitted to. This sealing function is not passive; it actively excludes harmful elements throughout the full range of the machinery's motion. The selection of the elastomer compound is crucial here. For instance, Nitrile rubber offers excellent resistance to oils and fuels, making it ideal for hydraulic rod applications, while EPDM provides superior protection against weathering, ozone, and steam. The design of the convolutions (the folds) also plays a role, as deeper folds can allow for greater compression and extension without compromising the protective envelope. By preventing the ingress of contaminants, rubber bellows directly preserve the integrity of lubricants, maintain surface finishes on精密 shafts, and prevent the electrochemical reactions that lead to corrosion. This proactive protection is a cornerstone of preventive maintenance, translating into fewer breakdowns and a more predictable maintenance schedule. For applications involving extreme temperatures or aggressive chemical splashes, the question of rubber bellows failure in harsh environments becomes a key design consideration, which is mitigated by choosing the right material and design specifications from the outset.

Choosing the incorrect elastomer is a common precursor to rubber bellows failure in harsh environments. The material must be chemically compatible with the surrounding media. A bellows that performs admirably in a dry, dusty sawmill may quickly degrade in a food processing plant washdown or an automotive underbody exposed to road salt. Engineers must consult chemical resistance charts and consider not just the primary contaminant but also secondary exposures like cleaning agents or temperature extremes that can accelerate degradation. The following table provides a concise comparison of common rubber bellow materials and their suitability against typical industrial challenges. This analysis is vital for anyone comparing EPDM vs silicone bellows for weather resistance or seeking a solution for a chemically intense process.

| Material | Best Resistance Against | Key Limitations | Ideal Application Example |

| Nitrile (NBR) | Oils, fuels, hydrocarbons, abrasion | Poor weather/ozone resistance, moderate temp range | Hydraulic cylinders, automotive engines, fuel systems |

| EPDM | Water, steam, weathering, ozone, mild chemicals | Poor resistance to petroleum-based oils and fuels | Outdoor machinery, pulp & paper processing, cooling systems |

| Silicone | Extreme high & low temperatures (-60°C to 225°C), oxidation | Lower tensile strength, poor abrasion resistance | Food/beverage heat seals, aerospace, high-temperature ovens |

| Neoprene | Moderate oils, weathering, fire resistance | Can be swollen by certain synthetic oils | General-purpose industrial covers, marine applications |

| Fluorocarbon (FKM/Viton) | High temperatures, aggressive chemicals, acids | Very high cost, poor low-temperature flexibility | Chemical processing, semiconductor manufacturing |

Industrial machinery is rarely static. Linear actuators extend and retract, pivoting joints rotate, and mounted equipment often experiences slight misalignments or vibrations. A rigid cover would quickly fatigue and crack under such dynamic conditions. The fundamental design of rubber bellows, with their flexible convolutions, allows them to compress, extend, bend, and twist in harmony with the component's movement. This dynamic compliance is essential for preventing the cover itself from becoming a point of failure. Beyond simple accommodation, the elastomeric nature of bellows provides inherent vibration dampening. In applications like printing presses, packaging machines, or vehicle suspensions, high-frequency vibrations can loosen fasteners, damage electronics, and create noise. A well-fitted bellow absorbs and dissipates a portion of this vibrational energy, contributing to smoother operation and protecting adjacent components. When specifying bellows for such dynamic roles, factors like the stroke length, minimum compressed height, and bend radius are critical to ensure the bellow does not experience excessive stress during its full cycle of motion. This is where the balance between the cost of custom rubber bellows for machinery and the need for a perfect fit must be evaluated, as an off-the-shelf solution may not always accommodate complex movement profiles.

The benefits of rubber bellows extend directly into the realms of workplace safety and total cost of ownership. From a safety perspective, bellows serve as a guard, preventing accidental contact with moving parts such as reciprocating rods or rotating shafts. This helps companies comply with machinery safety standards (like OSHA or CE directives) by containing potential pinch points and preventing loose clothing or tools from being drawn into machinery. Furthermore, by containing grease, lubricants, or process materials within a system, they prevent slip-and-fall hazards from leaks and contribute to a cleaner, more organized worksite. In terms of longevity, the protective functions previously discussed coalesce to deliver a powerful return on investment. Preventing contamination and accommodating movement directly reduces wear on expensive core components like servo motors, precision guides, and hydraulic seals. This translates into fewer unplanned stoppages, lower spare parts inventories, and a significant extension of the mean time between failures (MTBF) for critical equipment. When evaluating the cost of custom rubber bellows for machinery, it should be viewed not as an expense but as an insurance policy that safeguards a far greater capital investment in the machine itself.

Even the highest-quality bellow can fail prematurely if installed or maintained incorrectly. Proper installation is the first critical step. This involves ensuring the bellow is not twisted or over-extended during mounting, that clamping bands (if used) are secure but not overtightened to the point of cutting into the material, and that the fixed and moving attachment points are aligned correctly. For maintenance, regular visual inspections are paramount. Technicians should look for signs of how to install and maintain industrial rubber bellows correctly to avoid common pitfalls. Key indicators of potential rubber bellows failure in harsh environments include surface cracking (checking), deep cuts or abrasions, permanent deformation or "set" in the folds, and discoloration or softening from chemical attack. A simple, scheduled inspection can identify these issues early, allowing for planned replacement during a shutdown before a catastrophic failure occurs. Understanding the rubber bellows lifespan expectation for automotive or industrial use, which varies by material and duty cycle, helps in setting an appropriate inspection and replacement schedule.

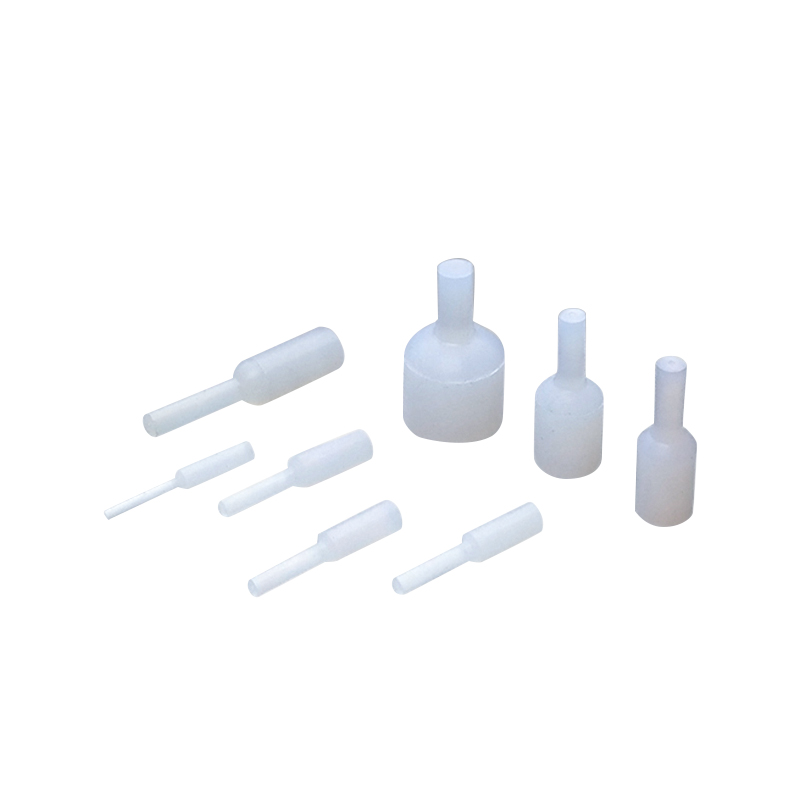

The true power of rubber bellows is unlocked through customization. While standard sizes cover many needs, unique industrial challenges often demand tailored solutions. The process of creating custom rubber bellows for pneumatic cylinders or other specialized equipment involves defining key parameters: the exact dimensions (bore, length, compressed height), the required material for chemical and temperature resistance, the number and shape of convolutions for the needed stroke, and the type of end fittings (e.g., flanges, bead rings, or clamping bands). Manufacturers use various molding and dipping techniques to produce bellows that perfectly fit the application. This bespoke approach solves space-constrained problems, meets unusual movement profiles, and addresses extreme environmental conditions that off-the-shelf products cannot. For example, a rubber bellows lifespan expectation for automotive suspension components might require a specific compound to withstand road salt, UV exposure, and constant flexing, which a standard product may not provide. Although the cost of custom rubber bellows for machinery is higher than standard parts, the value lies in perfect performance, enhanced durability, and the elimination of compromises that could lead to system failure.

The most common indicators of impending or ongoing rubber bellows failure in harsh environments are physical degradation signs and performance issues. Visually, look for cracking (often starting at the creases of convolutions), splitting or tearing of the material, permanent deformation where the bellow no longer returns to its full length, and signs of chemical attack like swelling, softening, or discoloration. Performance-wise, if contaminants are found inside the area the bellow is meant to protect (e.g., grease is dirty, rods are scored), the bellow has likely failed its primary sealing function. Prevention starts at the design and selection phase: rigorously matching the elastomer material to the environmental exposures (chemicals, temperature, UV) and ensuring the bellow is rated for the required range of motion. Proper installation without twisting or over-extension is critical. Finally, implementing a routine inspection schedule as part of preventive maintenance allows for replacement before a minor issue leads to major component damage.

The choice between EPDM vs silicone bellows for weather resistance and high-temperature use hinges on the specific nature of the "outdoor" or "high-temperature" conditions. EPDM is the champion of general weather resistance. It offers outstanding resistance to ozone, UV radiation, and water (including steam), making it an excellent, cost-effective choice for most outdoor machinery, cooling tower systems, or applications with frequent washdowns. Its temperature range (typically -50°C to 150°C) is suitable for many industrial settings. Silicone, on the other hand, excels in extreme temperature breadth, performing reliably from as low as -60°C to over 200°C continuously. It also has superior resistance to prolonged dry heat and oxidation. However, silicone generally has poorer tensile and tear strength, making it less suitable for high-abrasion environments. For a purely outdoor application with wide temperature swings but minimal physical abuse, silicone may be best. For a hot, wet, and slightly abrasive outdoor environment, EPDM is often the more durable and economical choice.

Providing a single number for the rubber bellows lifespan expectation for automotive or similar demanding industrial settings is difficult, as it depends heavily on the material quality, exact environment, and duty cycle. In a highly aggressive environment like an automotive underbody, bellows are subjected to road salt, water, stones, ozone, oil splashes, and constant vibration. A high-quality bellows made from a compound like chlorinated polyethylene (CPE) or a specially formulated EPDM/Nitrile blend, properly installed, might have a target lifespan aligned with vehicle service intervals, often in the range of 5 to 10 years. However, severe service can shorten this. In general industrial settings, lifespans of 1 to 5 years are common for bellows under constant motion and exposure. The key is to establish a inspection routine—if a bellow shows significant cracking, hardening, or other damage before its expected lifespan, it indicates the material may be underspecified for the application.

Evaluating the cost of custom rubber bellows for machinery requires a holistic view of value versus price. Standard bellows are a great fit for common, low-risk applications. However, custom bellows become worth the investment when standard parts force compromises that risk system performance or longevity. If a standard bellow does not fit perfectly, it may rub against components, fail to seal properly, or restrict the full range of motion, any of which can lead to premature failure of the bellow or, more critically, the expensive component it protects. A custom solution ensures optimal material selection for the specific contaminants present, perfect dimensional fit to avoid stress points, and design features that accommodate the exact movement profile. The "extra cost" should be weighed against the cost of unplanned downtime, a ruined ball screw or hydraulic cylinder, and lost production. In most critical or harsh applications, the custom bellow is the more cost-effective choice over the machine's lifecycle.

Correctly understanding how to install and maintain industrial rubber bellows is essential for achieving their full protective potential and lifespan. For installation, first, ensure the component and mounting surfaces are clean and free of burrs. Carefully stretch or position the bellow without twisting it. If using clamping bands, ensure they are centered and tightened evenly to the manufacturer's specification—overtightening can cut the material. Verify the bellow can move freely through its entire range without pinching or excessive stretching. For maintenance, establish a visual inspection schedule. Look for the signs of failure mentioned earlier: cracks, tears, chemical degradation, and accumulated debris that could be abrasive. Keep the bellow clean with compatible cleaners; avoid high-pressure sprays directly at seals. Most importantly, replace the bellow at the first sign of significant wear or as part of a scheduled preventive maintenance plan, never waiting for it to completely fail. Keeping a spare on hand for critical applications can minimize downtime during change-outs.