2026-01-14

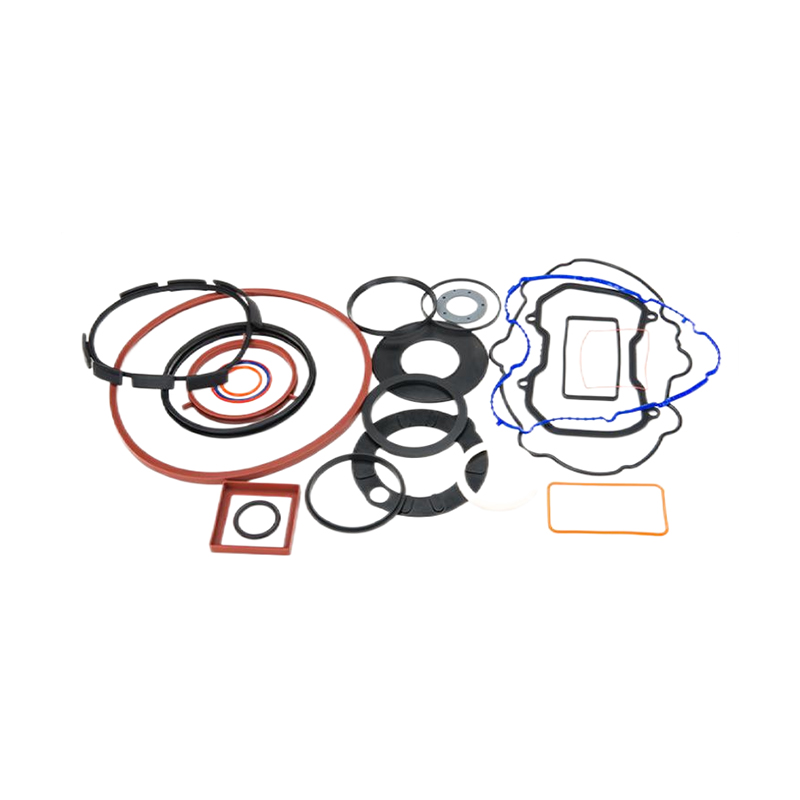

Ensuring reliable sealing in industrial machinery is critical for operational efficiency, leak prevention, and equipment longevity. Selecting the correct Rubber Washer Flanged Gaskets involves evaluating material compatibility, mechanical requirements, and environmental conditions. This guide provides a comprehensive, engineer-level approach to selecting these gaskets for industrial applications.

The gasket market continues to grow globally due to increasing industrial activity, stringent safety regulations, and expanding infrastructure projects. According to the latest report by Future Market Insights, the global gasket and seal market is projected to exceed USD 23 billion by 2032, driven by demand in machinery, automotive, and construction sectors. Rubber Washer Flanged Gaskets occupy a crucial niche in medium-pressure sealing applications where alignment and compressive distribution are essential.

Source: Future Market Report

Jiaxing Tosun Rubber&Plastic Co., Ltd. is a comprehensive private enterprise integrating R&D, production, and trade of rubber and plastic products. Covering 15,000 m² with 250+ staff, including 12 mold engineers and a 20-person inspection team, the company can rapidly design molds and produce custom Rubber Washer Flanged Gaskets to meet precise customer requirements.

For SEO and B2B visibility, the following long-tail keywords are relevant for Rubber Washer Flanged Gaskets:

Material selection is the foundation for ensuring long-term performance. Elastomers like NBR, EPDM, and silicone provide varying resistance to temperature, pressure, and chemicals. Understanding these differences is essential for matching Rubber Washer Flanged Gaskets to machinery requirements.

| Property | NBR | EPDM | Silicone |

| Temperature Range | -40 to 120°C | -50 to 150°C | -60 to 200°C |

| Chemical Resistance | Oil & fuel | Water, steam, weather | High temperature, broad chemicals |

| Typical Applications | Hydraulic systems | Water pipelines | High-temperature machinery |

The gasket must withstand the machinery’s thermal and pressure loads. For systems with elevated temperatures, select materials like silicone or fluorosilicone. Pressure ratings should align with flange specifications to prevent compression set or leakage.

Industrial environments often expose gaskets to aggressive chemicals. EPDM is suited for aqueous and mild chemical systems, while FKM or silicone can resist acids, bases, and solvents. Selecting incompatible materials may lead to rapid degradation and unplanned downtime.

Custom rubber washer flanged gaskets supply ensures optimal flange alignment and compression. Standard sizes may not provide consistent sealing in specialized machinery, making custom fabrication essential for critical applications.

Proper clamping prevents leaks without over-compressing the gasket. Engineering calculations for compression rates relative to flange stiffness optimize performance and extend service life.

Flange surface roughness and finish influence sealing reliability. Standards such as ASME B16.1 provide guidelines for acceptable finishes. Inadequate surface preparation increases the risk of gasket failure.

| Feature | Standard Gaskets | Custom Gaskets |

| Lead Time | Short | Moderate |

| Fit Precision | General | Exact |

| Cost | Lower per unit | Higher setup cost |

| Performance | Broad applications | Optimized for specific conditions |

Jiaxing Tosun Rubber&Plastic Co., Ltd. employs rigorous testing to ensure gasket performance. Compression set, hardness, and chemical degradation tests are conducted to verify compliance with design specifications, ensuring longevity and reliability in industrial machinery.

Modern industrial applications increasingly require compliance with non-asbestos materials and low emission standards. Adhering to recognized international standards ensures operational safety and regulatory alignment.

Source: ISO Sealing Standards